THE CASH RAILWAY WEBSITE |

||||||||

| Home | Manufacturers | Cash Balls | Wire systems | Cable systems | Pneumatic systems | Locations | References | Patents |

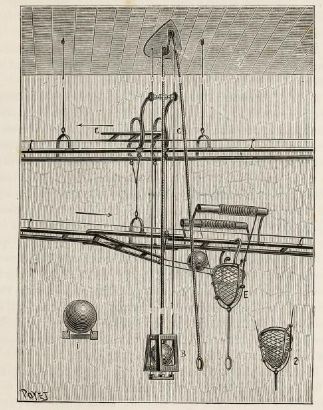

Cash Ball system

|

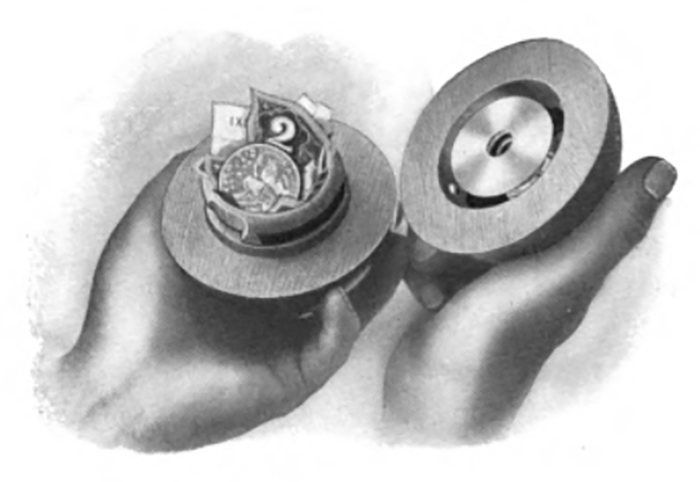

The Cash Ball system was invented in 1881 or 1882 and manufactured until the 1930s. The cash is conveyed in hollow wooden balls, running along a pair of inclined tracks. The top one slopes down from sales point to cashier and the bottom slopes the other way. The gradient is 5/16ths of an inch to the foot. A patent of 1887 mentions ball sizes of 3¼ to 3¾ inches diameter, though perhaps the range was a bit greater. There could be as many as seven different sizes in steps of 1/8 inch, depending on the number of stations to be served along one line - see below. The system is well described in an article from the Belfast News-Letter of 1885 and there is considerable technical detail in an article in the St Louis Daily Globe Democrat about the system installed in the Penny & Gentles store. It is said to be the first one to have a "switch" (i.e. point) to allow the return track to have branches. At each switch, larger ball would strike a trigger above the track, which would activate the switch and allow the ball to pass on along the "main line". Smaller balls would not engage the trigger and be diverted along the "branch line". Hence the ball could be returned to the right sales point. This can be well seen in a video of the reconstruction by David Holt. According to Lamson trade cards of the 1880s (Ephemera Society of America website), systems were originally leased at a rate depending on the number of stations. The smallest system was four stations at $125 for the first year, an additional station was $10 and a system of 25 stations was $450. The rails were made of hardwood, about ¾ inch square and a few inches apart. They were lined with narrow strips of leather to make the system quieter. The balls were originally made of boxwood from one block, by hand, and were very expensive. By 1888 they were being made by machine in two pieces from maple or birch and the cost was reduced by 90% (Lowell Daily Courier). In later years it was difficult to obtain replacement balls: Lamsons used to make them at Hythe Road, London out of substandard mangle rollers. The money was held in place by means of metal discs on springs. This was to prevent it rolling about and retarding the ball as it travelled along the track. Each track could have from one to seven stations along it and each station would have its own size of ball. At each station there was a ramp, held on a pivot. If the ball was above a certain diameter, it would actuate a lever which would drop the ramp and cause the ball to run off the main track at that station. Smaller balls would continue along the track until they reached their correct station - the smallest ball having the longest journey and the largest belonging to the station nearest to the cashier. This is spelled out in Cork Constitution, 11 Sep. 1885, p.2: "The balls are of different sizes, and are lettered A B C, etc., while the lines are numbered; so that the ball with A 1 printed on it, when put on the first line, will stop at the first station, and the one with A 2 will stop at the second. The large ball, when it comes to its proper station, strikes a trencher over it, which lets fall a trap, through which the ball falls, and can be taken off by the assistant at the counter. The smaller the ball the further it will travel, so that the smallest ball is intended to stop at the last station on the line..." An improvement to the design of the ball was patented by Henry Soper, son of Alderman S.H.Soper of North-street, Brighton (presumably the owner of Soper's shop). It had been found that, after a certain amount of usage, the carrier balls developed an unfortunate habit of falling apart, thus imperilling the safety of the money that they contained, not to mention the heads of those beneath. To remedy this, Mr Soper devised a plan of fixing to the threads of the respective halves of the ball a steel collar with spring action, by means of which they were firmly interlocked. The rights were purchased by Lamsons. Brighton Herald, 22 Jun. 1889, p. 3 Another reported fault of the system was that the ball sometimes fell off the track and broke the counter case below it Murphy, Modern drapery The cash ball system is described by Mr J. Branch, an employee of Lamson Engineering from 1930 to 1974, in a letter to the Daily Mirror, 11 July 1977, p.20. He says that the track dropped two inches in every 8 feet [which would be ¼ of an inch per foot]. He lived in Birmingham and the last shop he remembers using the system was the Central Drapery in Smallbrook Street. As far as I know there are no systems still in use, but there are working systems at Beamish Museum in England and The Up-to-Date Store, Coolamon in Australia. There is a sound recording from a draper's shop in the BBC Sound Effects collection. |

|||

This photograph shows the 8-station system installed at Alexander Moon Ltd in Galway in November 1894. Note the ball approaching a "switch" - the switch was set by the size of the ball so that it came back along the correct branch. (The picture on the Introduction page shows a controlled switch incorrectly installed on the upper track.) There is a big separation between the outward and return tracks at this end. In 1965 it was replaced by Paragon Registers and was

acquired by Lamsons. |

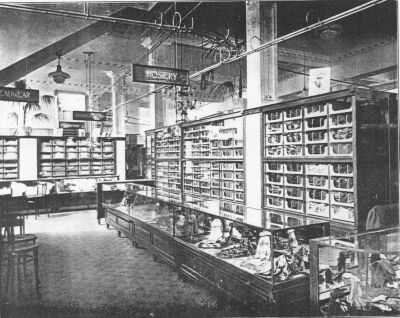

A cash ball system in the hosiery department of a store, taken from Modern draper (London: Caxton, 1924) |

||

An open cash ball. Lamson catalogue of 1912 |

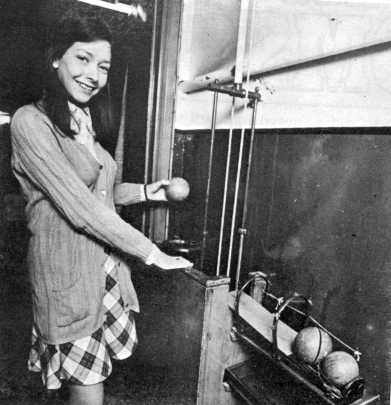

A late survivor into the 1970s was Topliss drapers of Louth. This is Miss Lorraine Parrish at the top of the lift to the first floor. © This England, 1975 |

||